Manufacturer

Sonnenleder. Leather from the Tanning Pit

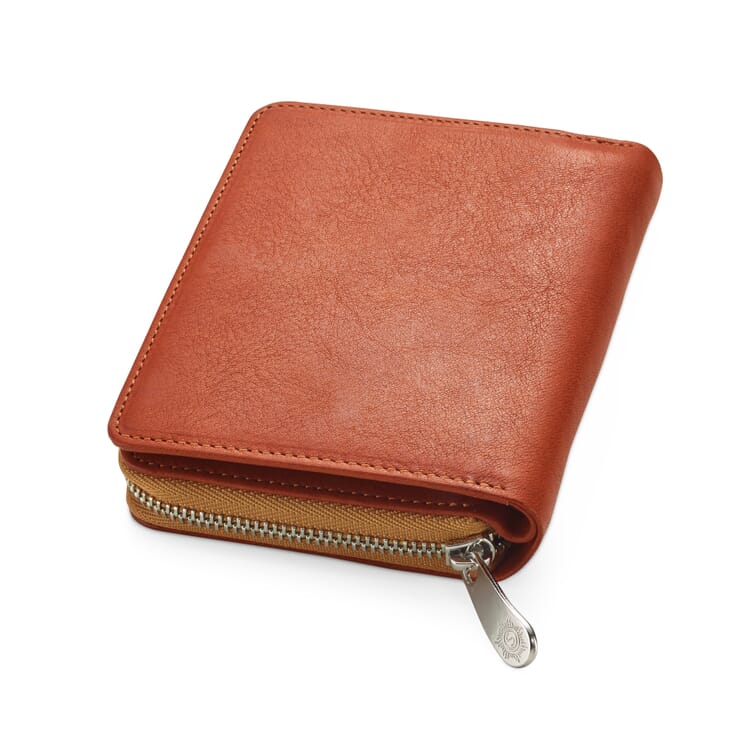

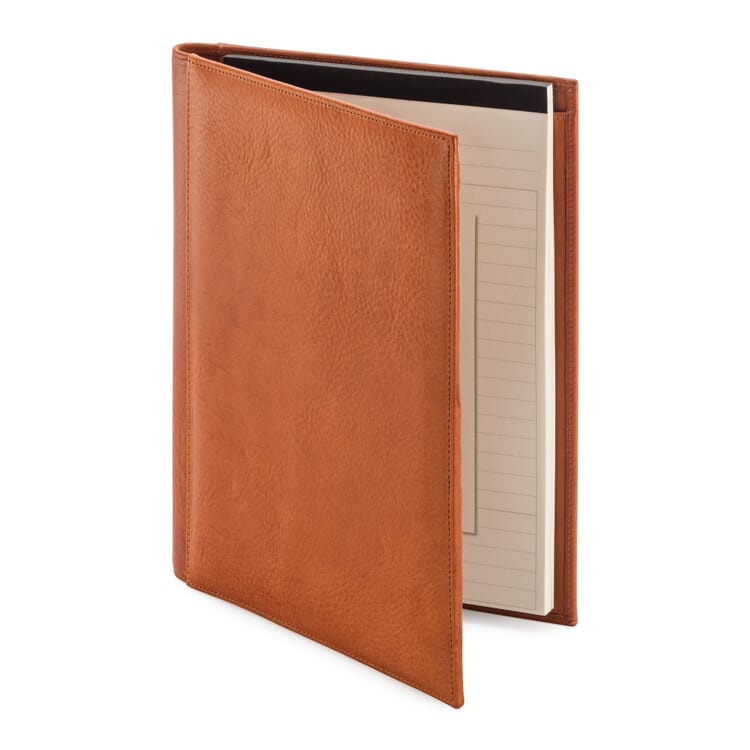

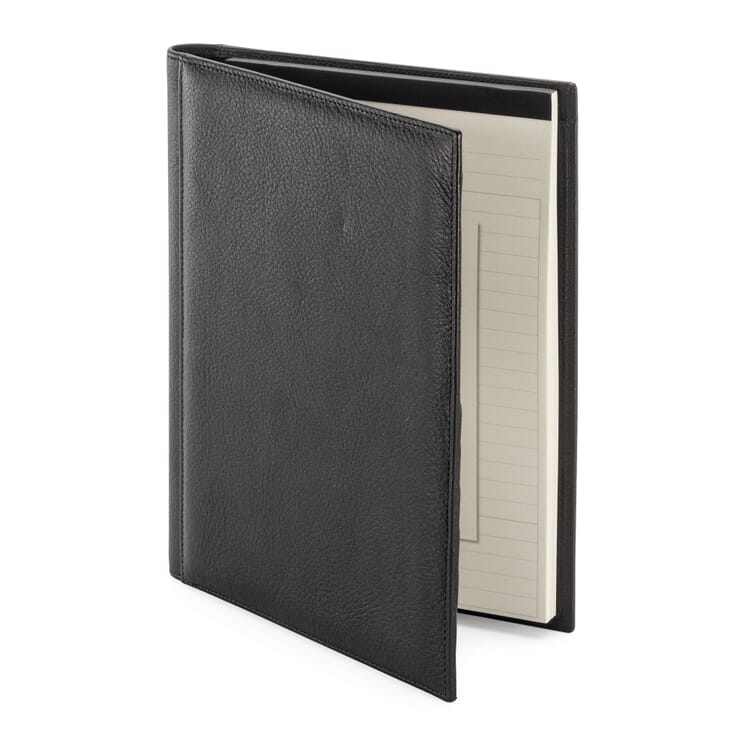

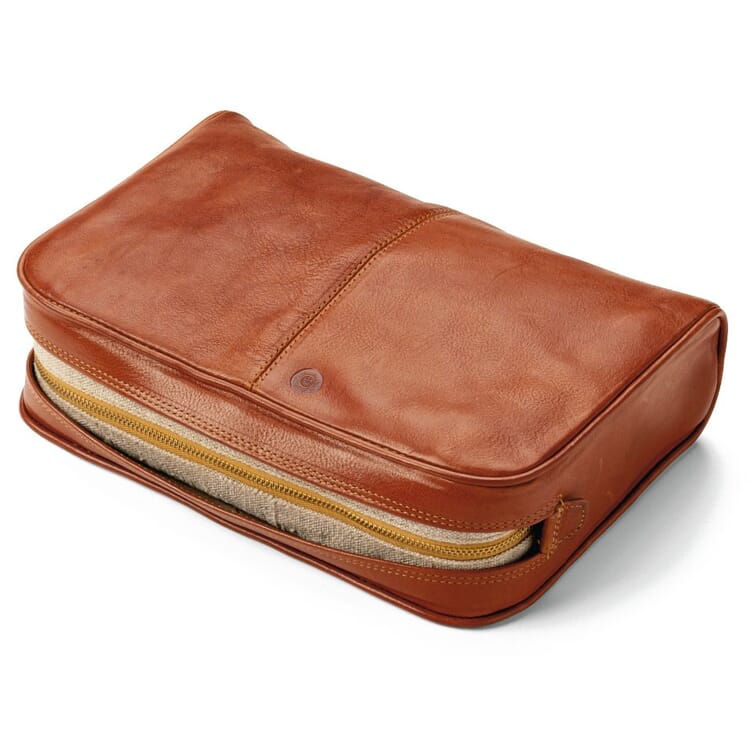

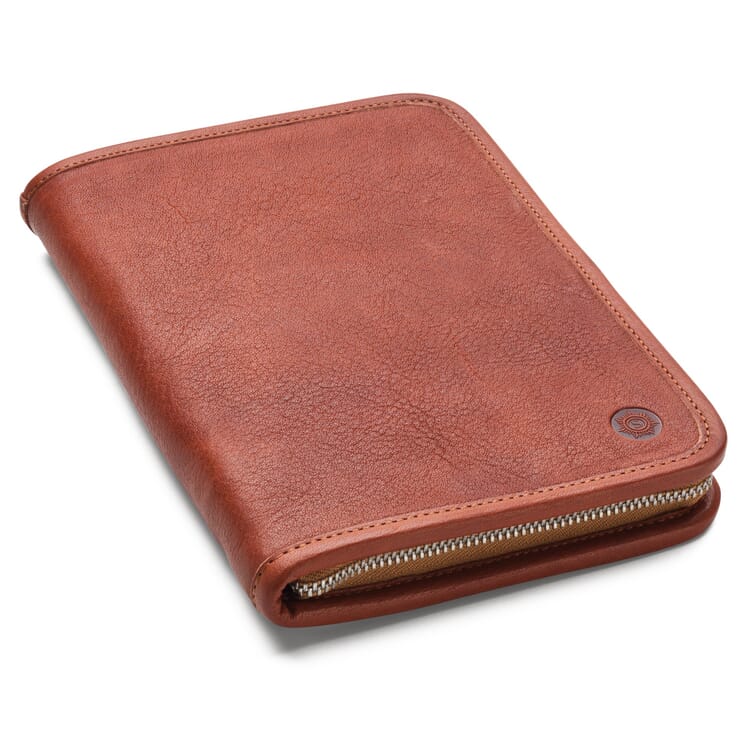

These leather articles are made by Sonnenleder from Bodman-Ludwigshafen on Lake Constance. Paying painstaking attention to the smallest details, Sonnenleder maintains traditional leather-making practices and stands for consistently functional styles and minimalist designs. The hides of south German cows are vegetable-tanned according to traditional methods and then air-dried.

The tanning agents contain extracts from bark, roots and fruits. In twelve tanning pits with slightly increasing concentrations of tanning liquids, they transform the protein fibres of the cowhides into leather fibres over a period of between six to twelve weeks. After tanning, the hides are air-dried and lubricated in an oil vat according to a well-kept secret recipe. In its pre-dyed state, the finished leather has a characteristic light brown, reddish colour (hence the term "red-tanned"), which looks different in every piece. With use and exposure to the elements, the leather changes colour and develops its own unique patina, which is distinctive of leather. Leather dyed with natural oils and fats in a vat also acquires its own shiny patina over time.