Recycled products. Less for the sea

Vast amounts of plastic waste have ended up in the world's oceans over the past 50 years and are floating around in the centers of major ocean currents. According to the WWF, each square kilometer of ocean already contains up to 46,000 plastic particles - and the trend is rising. This is because between 6-10% of the total polymer production ultimately ends up in the Atlantic, Pacific or Indian Oceans via very different routes. It can take 350 to 400 years for plastic waste to completely decompose. This is just as true for the shopping bag carelessly left behind as for the PET bottle disposed of in the sea or the yogurt cup forgotten on the beach. Time enough, therefore, for it to enter the food chain of marine animals, birds and, ultimately, humans, with consequences that are as yet incalculable.

Collecting, sorting and reusing plastic waste in higher-value products currently seems to be the best way out of the dilemma. After all, what doesn't end up in the ocean in the first place doesn't pose a threat to sensitive ecosystems. Socks made of nylon from fishing nets, floor coverings made from old car tires, or bags made from bicycle inner tubes and truck tarpaulins are some of the product ideas that have already been established on the market for some time. "We have to learn to recycle the whole buffalo again!" is how Dr. Sascha Peters from the future agency HAUTE INNOVATION in Berlin aptly comments on the current situation.

Ecoalf. Yarns from recycled PET bottles, fishing nets and car tires.

The waste of raw materials in our throwaway society first drives Spaniard Javier Goyeneche up the wall and then gives him an idea. In 2009, the designer founded his label Ecoalf, which has since produced clothing and accessories from recycled materials. As part of the Ecoalf ocean project, fishing nets, PET bottles and old car tires are transformed into polyamide yarn and made into robust fabrics. The manufacturing processes, some of which are carried out mechanically, are complex - Goyeneche had to invest a good year just to find companies capable of doing this. A small patch on each Ecoalf product informs its wearer about the resources used in its manufacture and thus provides information on the ecological balance sheet.

Lefa - a material against waste

Some materials inherently have a high resource-saving and thus sustainable component. Leather fiber, so-called Lefa, is such a substance. High-quality "bonded leather" consists of over 90% renewable raw materials. More than half of it is recycled leather residues, otherwise more likely to end up in landfills: offcuts from the leather processing industry and chrome shavings, which are produced in large quantities when freshly tanned leather hides are folded in tanneries. But Lefa is not only convincing from a waste-economic point of view.

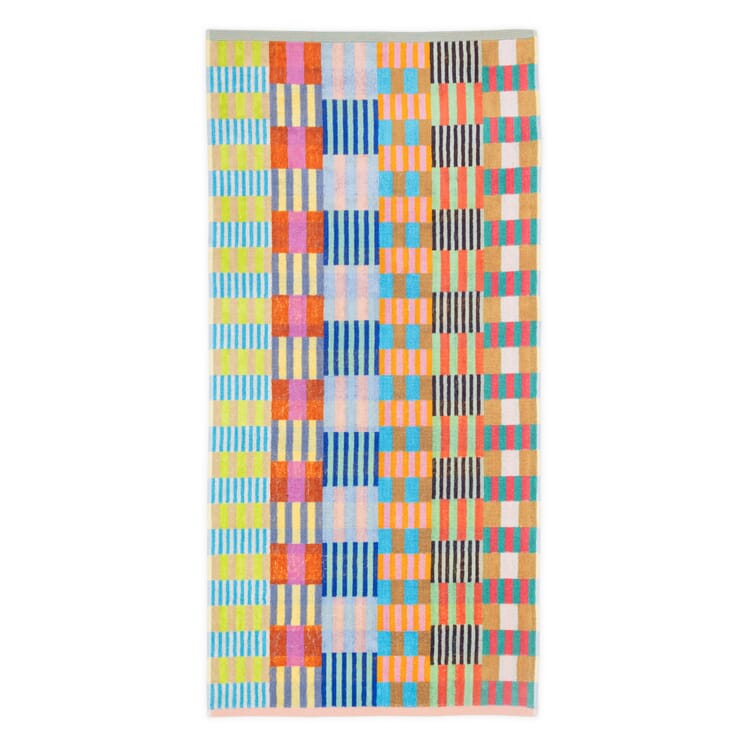

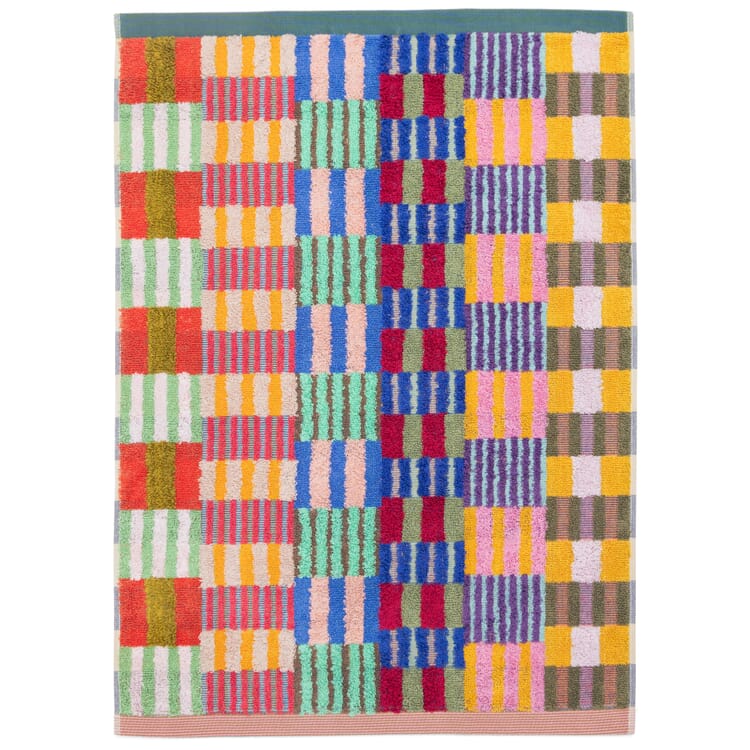

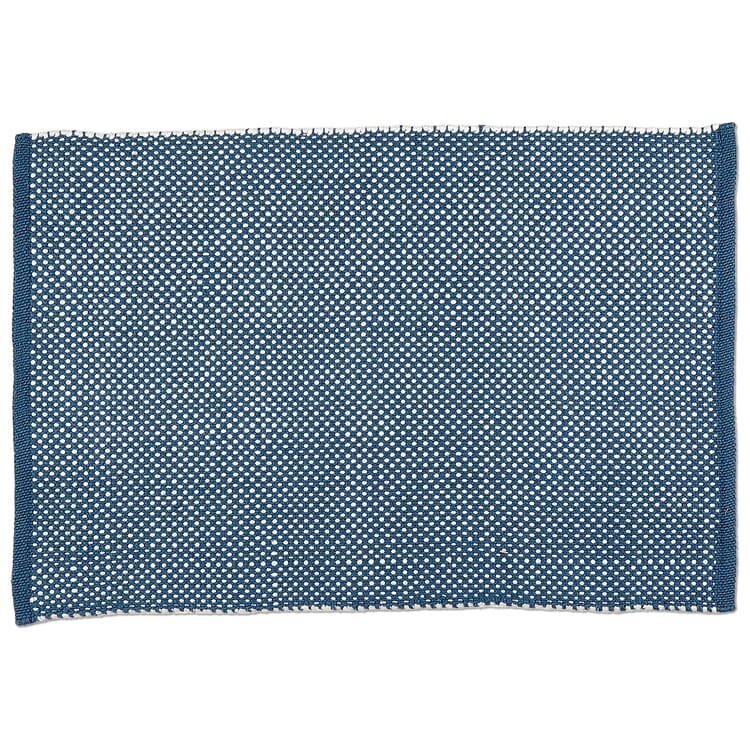

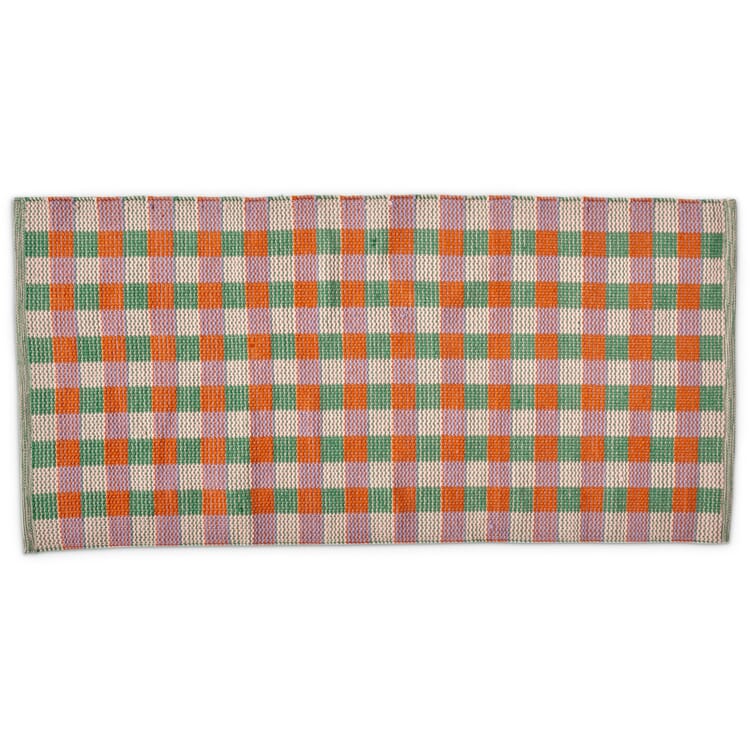

Our products from recycled materials

Manufactum is also increasingly focusing on reducing waste in other ways, for example by increasingly offering products made from recycled raw materials. The plant bags or rugs made from recycled PET bottles and the apple food dispenser made from recycled plant pots are examples of a strategy that can enable a more conscious use of our resources. After all, compared to energy recovery in a waste incineration plant, the material recycling of polymer material saves 1.26 tons of CO2 per ton of plastic recycled.