Manufacturer

Expertise and precision from the Ore Mountains. Precision engineering K. Fischer

The Ore Mountains have an eventful economic history, which has been and continues to be shaped primarily by small, medium-sized, often owner-managed businesses. Ore mining once brought the region global renown, but today it is primarily known for its closely associated folk art, the products of which are made in smaller woodworking stores. But for decades, the Ore Mountains have also produced precise and solid measuring instruments for meteorology and climate monitoring, which are characterized by the best workmanship - from Feingerätebau K. Fischer GmbH in Drebach.

When the aviation engineer Kurt Fischer founded the company in 1945, it was still located in the middle of Drebach, in the large classical building of a former stocking factory - an early example of industrial reuse. Fischer was nationalized in 1972 and from then on operated under the name "VEB Feingerätebau Drebach". After reunification in 1990, "father's former company", as the state-owned enterprises were popularly known in the GDR, returned to the Fischer family. However, the company building was too large and outdated. A few years later, the decision was made to build a new building and move the historic machines to their current location on the edge of the village - on a hillside with a view of the valley and town. Production is located on the first floor and administration on the upper floor. Peter Fischer, the grandson of the company founder, works there. He takes us on a tour of the production facility, where almost all product components are manufactured and assembled. It immediately becomes clear how much technology, expertise and precision goes into each of Fischer's weather measuring instruments.

Decisive basis. The production

There is the can soldering shop. This is where metal membranes are soldered together to form the cans, the heart of the barometers. They are made of a corrosion-resistant copper-beryllium alloy, which is ideally suited for pressure measurement thanks to its remarkable elasticity and high resistance to ageing. The cans, inside which there is a vacuum, expand at low air pressure and contract at high pressure. This change is then transferred to the pointer of the barometer. The technology has been mature and highly precise for many decades. "You will therefore find copper-beryllium cans in all good barometers," explains Peter Fischer.

The scale print shop is right next door. Small batches are printed there using the conventional screen printing process - in black, in color and also according to customer-specific wishes. Two employees pull the hand squeegees over the screen printing stencils with a practiced grip, evenly distributing the ink on the scale base, which at Fischer is always made of anodized aluminium. The extensive archive of wood-framed printing screens is stored in several meters of cabinets.

When you think of measuring instruments, you first think of metal, but many of Fischer's barometers, hygrometers and thermometers are also available in wood. Only high-quality beech, oak and ash wood, mostly of German origin, is processed in the company's own joinery, which Fischer obtains from a well-known supplier. The chips extracted from the wood processing workstations are used to fire the chip heating system, which Fischer uses to heat the company premises. If there are not enough chips from the company's own production, pellets are bought in.

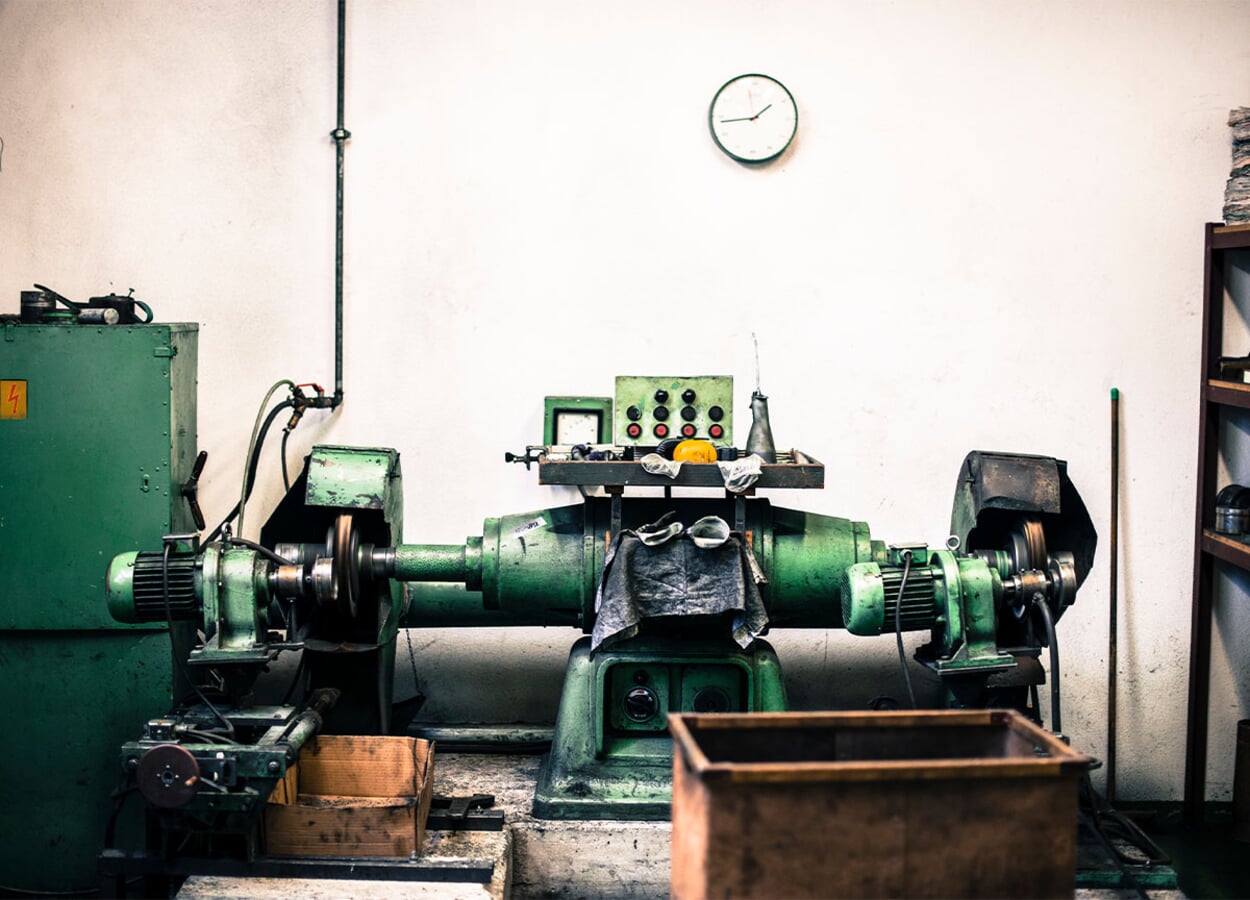

A considerable amount of space is taken up by the metalworking hall, where the mechanical concert of presses, punches and lathes can be heard unmistakably. Here, cases are drawn, individual parts for the movements are punched and bezels are turned with a diamond. A Russian eccentric press that stands on its own foundation catches the eye - it was not easy to move it here from the old building. A brass belt runs through it and, once set up, it goes "bang, bang, bang". Several linear meters on the wall fill shelves with embossing dies and other tools for setting up the machines. Polishing the metal parts is still done by hand on the polishing machine. According to Fischer, this is the only way to live up to the company's commitment to quality. Assembly is of course also carried out by hand, at ergonomic workstations arranged in a U-shape, where the individual parts are joined together.

Decisive fine-tuning. The adjustment

The final step to a precise weather measuring instrument is the adjustment chambers. Fischer movements are all specified with a certain accuracy. Adjustments are made until the pointer conforms to the scale, a final check is carried out and only when the instrument is within the specified tolerance is it allowed to leave the factory. The hygrometers, for example, are set in a two-point adjustment: The first value is provided by chambers with a saturation humidity of 100%, while the second value is determined by the current room humidity. It is important that the natural ageing process of the hair has already taken place in the measuring units, which is why the hygrometers are constantly exposed to fluctuating humidity levels before the final adjustment in order to anticipate it: "If the hair is fresh and you adjust it, then it is correct for the moment. But when the ageing process sets in, which will always happen, the hygrometer would become inaccurate." Finally, in the middle of the building is the central warehouse with the few purchased parts such as glasses, movements and packaging materials. There is also a small finished goods warehouse with catalog standard goods. Small, because individuality is one of Fischer's strengths and more than 95% of production is based on individual customer requirements.

It's actually "just" physics

Word of the company's good reputation has long since spread throughout Germany. Even in Swabia, where Lufft ceased production of mechanical measuring devices a few years ago. Since then, they have been manufactured under license by Fischer. Incidentally, the highest accuracy is achieved with the barographs and precision barometers, Fischer's flagship products. Customers for the latter are the professional shipping industry, the US National Weather Service and the US government, which has them fitted to US Navy ships and submarines. Peter Fischer says confidently: "I would say that we build the best mechanical barometer in the world." And adds modestly: "Actually, it's 'just' physics." He knows what he's talking about. Fischer grew up with the company from an early age. His parents worked there, he himself worked there as a pupil and student and the company was always a topic of conversation in the family circle. At 27, he was the boss and was thrown in at the deep end. Of course, he also had to learn the ropes. The routine and serenity he has today only came with practice. And it wasn't always easy economically either: since 2015, Fischer has therefore been working with a parent company, a regional investment company that is involved in innovative, future-oriented companies in Saxony's SME sector. However, the enthusiasm for the business has always been there. That is why it is also a core concern of Peter Fischer to maintain the craftsmanship, because: "There are many activities that you can learn, where it really only depends on skill. But everything here stands and falls with the employees' wealth of knowledge. It is therefore important to pass on this knowledge and experience to the younger generation in good time."