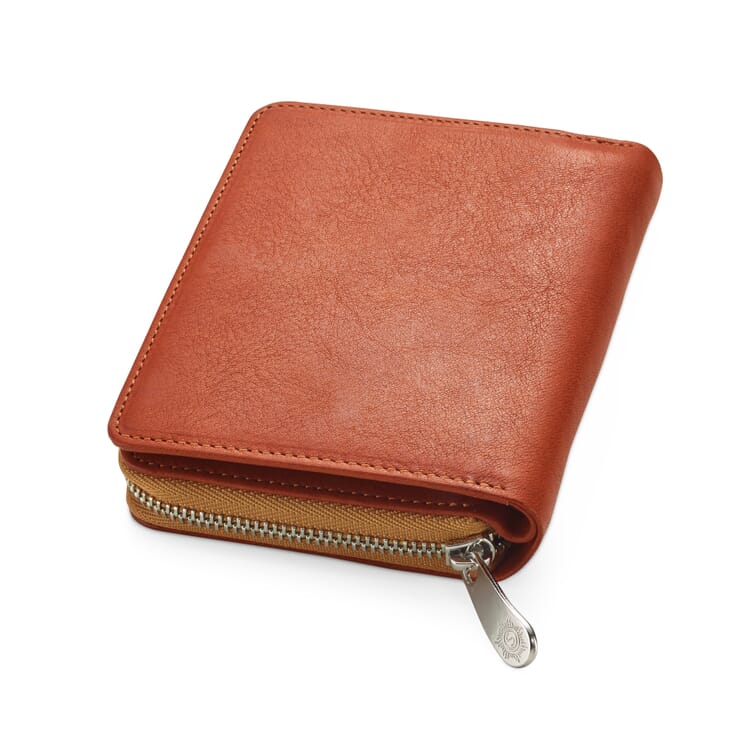

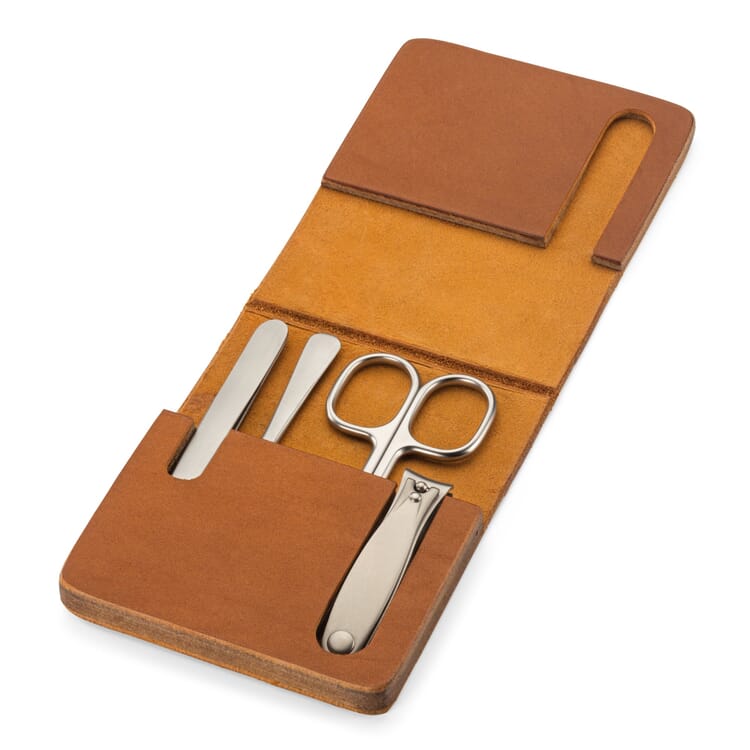

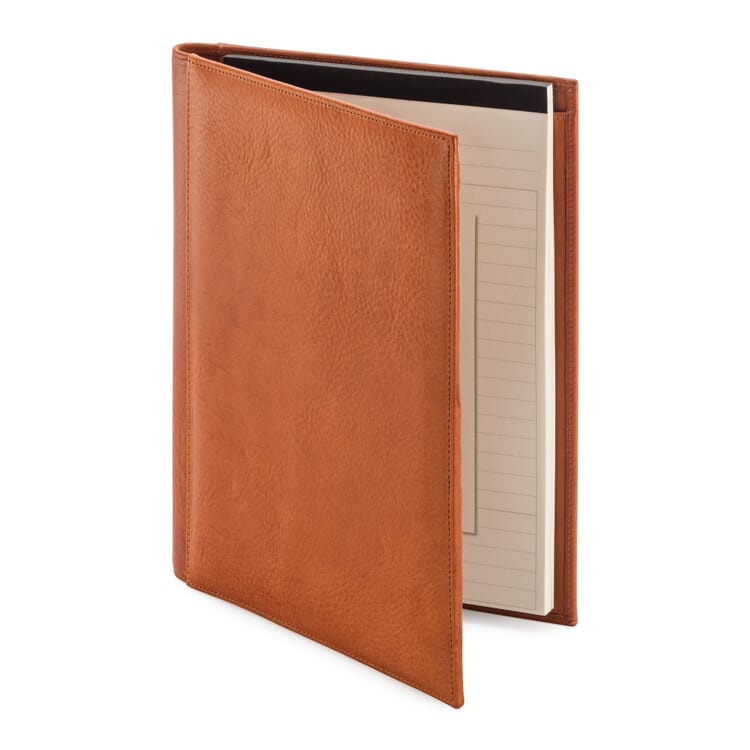

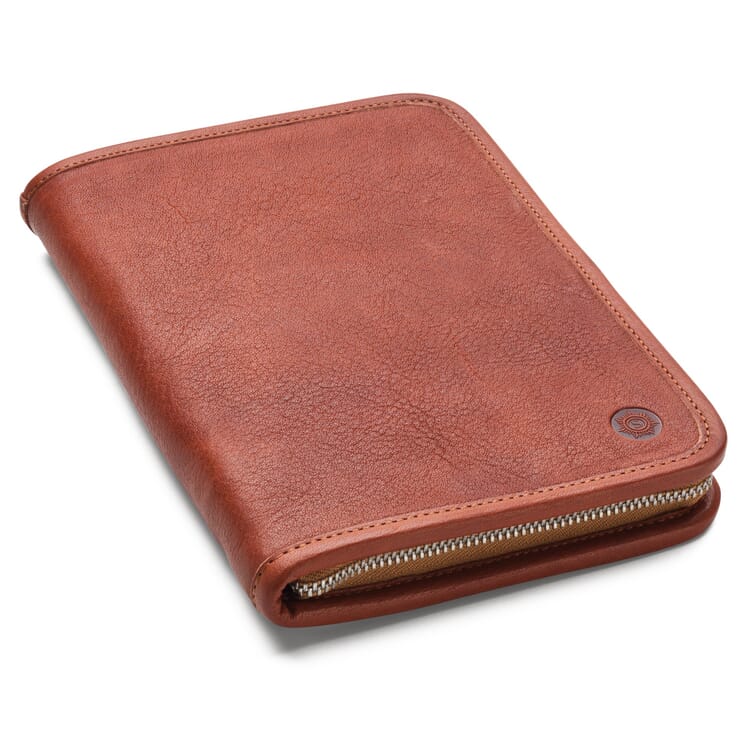

Material

Cowhide leather. Exceptionally robust and tear resistant

Cattle belong to the horned cattle family (Bovidae) and have been raised as livestock for thousands of years across the globe. As one of our most important suppliers of milk and meat, they are of great importance to the food industry. The raw hides that are a byproduct of this process are processed into cowhide through tanning. Because there is an abundant supply, cowhide is one of the most common and affordable types of leather. Worldwide, Brazil and India are among the largest suppliers, while in Europe Italy, Spain and Germany are the main producers.

The properties of cowhide

Cowhide can be very strong and thick, which is why it can be split into several layers either before or after tanning and used in a variety of ways. The thinner layers are lighter and more pliable and are therefore preferred for making clothing. Medium-weight layers are strong and durable, which is why they are used as furniture leather, for suitcases, bags and purses. Non-split full cowhide is processed into shoe soles. Moreover, the material has other valuable properties that are also used in our products made of cowhide: - First and foremost, cowhide is characterized by the fact that it is exceptionally tear and abrasion resistant thanks to its long and interwoven fibers. It is extremely robust and durable, so that cowhide can withstand even heavy use. Products made from it, such as bags, purses, backpacks, furniture and motorcycle clothing, are for this reason especially durable - In addition, cowhide is stretchable in moderation. Clothing and shoes made of cowhide therefore adapt to the body and the individual foot shape - Due to the size of the animals, the raw hides are also quite large. Cowhide is therefore ideal as furniture leather. - Cowhide is also water vapor and air permeable, thus breathable, so moisture can not easily accumulate.

The different qualities of cowhide

- Quality differences according to skin parts: The different skin parts of the beef - croupon (back), flanks (belly) and neck - also differ in their fiber structure after processing into leather. The highest quality part is the croupon, as it is the strongest. The leather from it has a firmer and denser fiber structure compared to leather from other parts of the hide - Differences in quality according to hide layers: The uppermost hide layer is called the grain split (also known as smooth leather, nappa or aniline leather after tanning), the lower layer is called the flesh split and the middle layer is called the core split (both also known as suede and suede leather after tanning). The grain split is considered more valuable because it has a denser and therefore more tear-resistant fiber structure and an individual grain pattern.

Depending on the type of leather, the quality and the product made from it, as well as the usage and wearing habits, leather requires the appropriate care. We have compiled comprehensive tips for you in our leather care guide.

Selected seating furniture with cowhide

Other products with cowhide

Recommended Topics

How much care a leather needs depends on various factors - for example, the particular leather goods and leather type, the use and wearing habits and also significantly on the quality of the leather. For high-quality leather jackets, for example, frequent wearing is the best care. This is because the leather is continuously tumbled and kept supple by the movement.

View moreCalf leather has an even, dense grain pattern, which is due to the closely spaced hair pores. Compared to the skin pattern of adult cattle, the pores are distributed over a smaller area. For this reason, calfskin is of higher quality and is preferred for fine leather goods such as accessories, clothing and shoes.

View moreTanning is the process by which animal hide acquires its resistance to water and decay. Protein fibers are converted into leather fibers in the process - a process that cannot be replicated synthetically. In addition to the nature of the raw material, the type of tanning determines the quality and properties of the leather end product: the strength, stretchability, water tolerance, hardness or suppleness of the leather are largely determined by the tanning process.

View more